In the ever-evolving realm of furniture design and production, precision is paramount. From sleek modern pieces to timeless classics, the quality of craftsmanship can make all the difference in both aesthetics and functionality. One technique that has revolutionized the way furniture components are crafted is vertical milling.

Understanding Vertical Milling

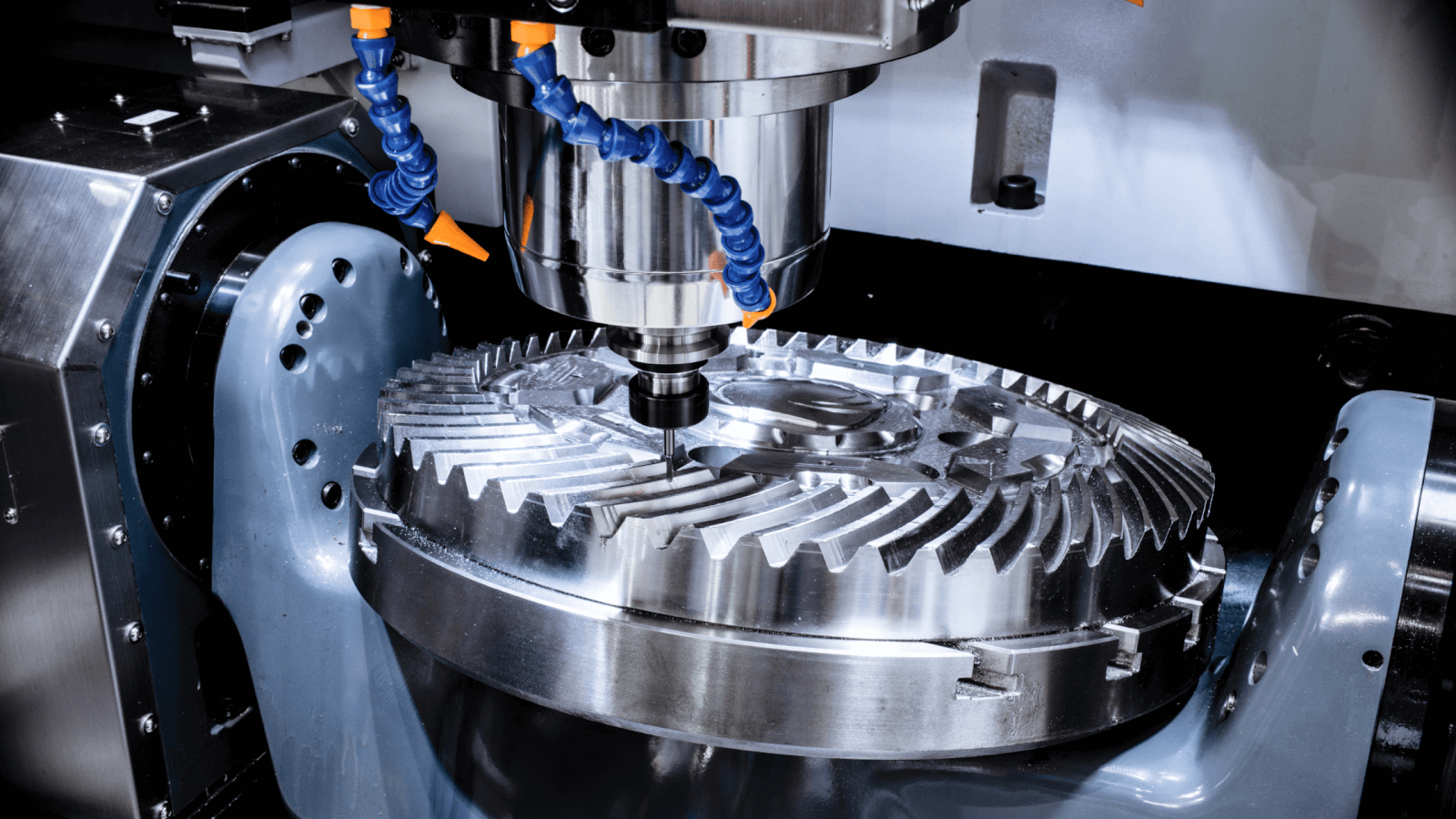

Vertical milling is a machining process that utilizes a vertically oriented cutting tool to remove material from a workpiece. Unlike traditional horizontal milling, where the cutting tool operates parallel to the work surface, vertical milling allows for greater precision and control, particularly when crafting intricate details and complex shapes.

In furniture manufacturing, vertical milling machines are used to carve out various components with remarkable accuracy. These components can range from table legs and chair backs to ornate decorative elements that adorn cabinets and shelves. The versatility of vertical milling makes it a preferred method for producing both standard pieces and custom-designed furniture elements.

Advantages of Vertical Milling in Furniture Production

- Precision Engineering: One of the primary advantages of vertical milling is its ability to achieve precise dimensions and intricate designs with ease. Whether it’s creating fine filigree patterns or precisely fitting joinery, vertical milling ensures that each component meets exact specifications, resulting in flawless furniture construction.

- Efficiency and Consistency: Vertical milling machines are equipped with computer numerical control (CNC) technology, allowing for automated machining processes. This automation not only improves efficiency by reducing production time but also ensures consistency across multiple pieces, maintaining uniformity in quality and design.

- Material Versatility: Vertical milling can be performed on a wide range of materials, including wood, metal, plastic, and composite materials. This versatility allows furniture manufacturers to explore innovative design concepts and experiment with different materials to achieve unique aesthetics and functionality in their products.

- Cost-Effectiveness: While vertical milling machines require initial investment, they offer long-term cost savings through improved productivity, reduced material waste, and lower labor costs. The precision and efficiency of vertical milling translate into higher-quality furniture pieces that command premium prices in the market.

Applications of Vertical Milling in Furniture Design

- Custom Furniture Production: With vertical milling, furniture designers have the freedom to create custom pieces tailored to individual preferences and specifications. Whether it’s incorporating intricate carvings or personalized engravings, verticalmilling enables designers to bring their creative visions to life with precision and accuracy.

- Reproduction of Antique Furniture: Replicating intricate details and ornate embellishments found in antique furniture requires meticulous craftsmanship. Vertical milling machines equipped with specialized cutting tools and software can accurately reproduce historical designs, preserving the authenticity and charm of classic furniture pieces.

- Integration of Modern Technology: Vertical milling also facilitates the integration of modern technology into furniture design. For example, incorporating hidden compartments for electronic devices or seamlessly integrating lighting elements into furniture components is made possible through the precision and flexibility of vertical milling techniques.

Case Study: The Evolution of Chair Manufacturing

To illustrate the impact of vertical milling on furniture production, let’s consider the evolution of chair manufacturing. Historically, crafting a single chair required skilled artisans to hand-carve intricate details and assemble individual components manually. This labor-intensive process limited production capacity and often resulted in inconsistencies in quality and design.

However, with the advent of vertical milling technology, chair manufacturing has undergone a paradigm shift. Designers can now create chair components with unparalleled precision and efficiency, from intricately carved legs to perfectly contoured seatbacks. CNC-controlled vertical milling machines streamline the production process, allowing for mass customization and rapid prototyping while maintaining the highest standards of craftsmanship.

Conclusion

In the world of furniture design and manufacturing, precision is the key to creating pieces that stand the test of time. Vertical milling has emerged as a game-changing technology that empowers designers and manufacturers to push the boundaries of creativity and craftsmanship.

By harnessing the precision, efficiency, and versatility of vertical milling, furniture elements are crafted with unparalleled accuracy, consistency, and quality, setting new standards of excellence in the industry. As the demand for custom-designed furniture continues to grow, vertical milling remains at the forefront of innovation, shaping the future of furniture production one precise cut at a time.