Ensuring efficiency, safety, and reliability is paramount in the intricate web of industrial pipelines. The backbone of this infrastructure lies in the clamping solutions that hold these pipelines together. Traditional clamps may suffice for basic applications, but in the dynamic landscape of modern industry, customized clamping solutions have emerged as the game-changer.

The Need for Customization:

Custom Pipe Clamps come in diverse shapes, sizes, and materials, catering to various processes across various sectors. Off-the-shelf clamping solutions often need to catch up when confronted with the unique requirements of these pipelines. This inadequacy can lead to compromised performance, increased maintenance costs, and even safety hazards. Customized clamping solutions address these challenges by offering tailor-made designs that precisely fit the specifications of each pipeline.

Enhanced Performance and Durability:

One of the primary benefits of customized clamping solutions is their ability to enhance the performance and durability of industrial pipelines. By meticulously designing clamps to match the exact dimensions and characteristics of the pipelines, engineers can minimize stress points, prevent leaks, and mitigate the risk of corrosion. This bespoke approach not only improves the efficiency of operations but also extends the lifespan of the infrastructure, resulting in long-term cost savings.

Optimized for Specific Applications:

Each industrial pipeline serves a unique purpose: transporting water, chemicals, oil, or gasses. Customized clamping solutions allow for optimization according to the specific requirements of these applications. For instance, pipelines carrying corrosive substances may require clamps constructed from corrosion-resistant materials such as stainless steel or specialized coatings. Similarly, pipelines subjected to high pressure or temperature fluctuations necessitate robust clamping mechanisms capable of withstanding extreme conditions without compromising performance.

Flexibility and Adaptability:

In an industrial landscape, adaptability is key to staying ahead of the curve. Customized clamping solutions offer the flexibility to seamlessly accommodate changes in pipeline configurations, expansions, or upgrades. Whether it’s integrating additional components, adjusting to shifts in operating conditions, or accommodating future maintenance needs, these bespoke clamps can be tailored to suit evolving requirements without requiring extensive modifications or replacements.

Streamlined Installation and Maintenance:

The precision engineering of customized clamping solutions streamlines the installation process, minimizing downtime and disruption to operations. Unlike generic clamps that may require tedious adjustments or modifications to fit, bespoke clamps are designed to align seamlessly with the pipeline components, facilitating swift and efficient installation. Moreover, their tailored design simplifies maintenance procedures, allowing for quick and hassle-free inspections, repairs, or replacements as needed.

Safety and Compliance:

Ensuring the safety and compliance of industrial pipelines is non-negotiable. Customized clamping solutions are pivotal in upholding these standards by providing reliable reinforcement and leak prevention mechanisms. These bespoke clamps reduce the likelihood of accidents, spills, or environmental hazards by eliminating potential weak points and enhancing structural integrity. Furthermore, they adhere to stringent regulatory requirements, ensuring industry standards and protocol compliance.

Cost-Effectiveness in the Long Run:

While the initial investment in customized clamping solutions may be higher than off-the-shelf alternatives, the long-term cost-effectiveness must be balanced. These bespoke solutions offer significant returns on investment over time by minimizing downtime, reducing maintenance expenses, and prolonging the lifespan of industrial pipelines. The enhanced performance, durability, and reliability translate into tangible savings and improved operational efficiency, making them a sound investment for any industrial facility.

Innovative Materials and Technologies:

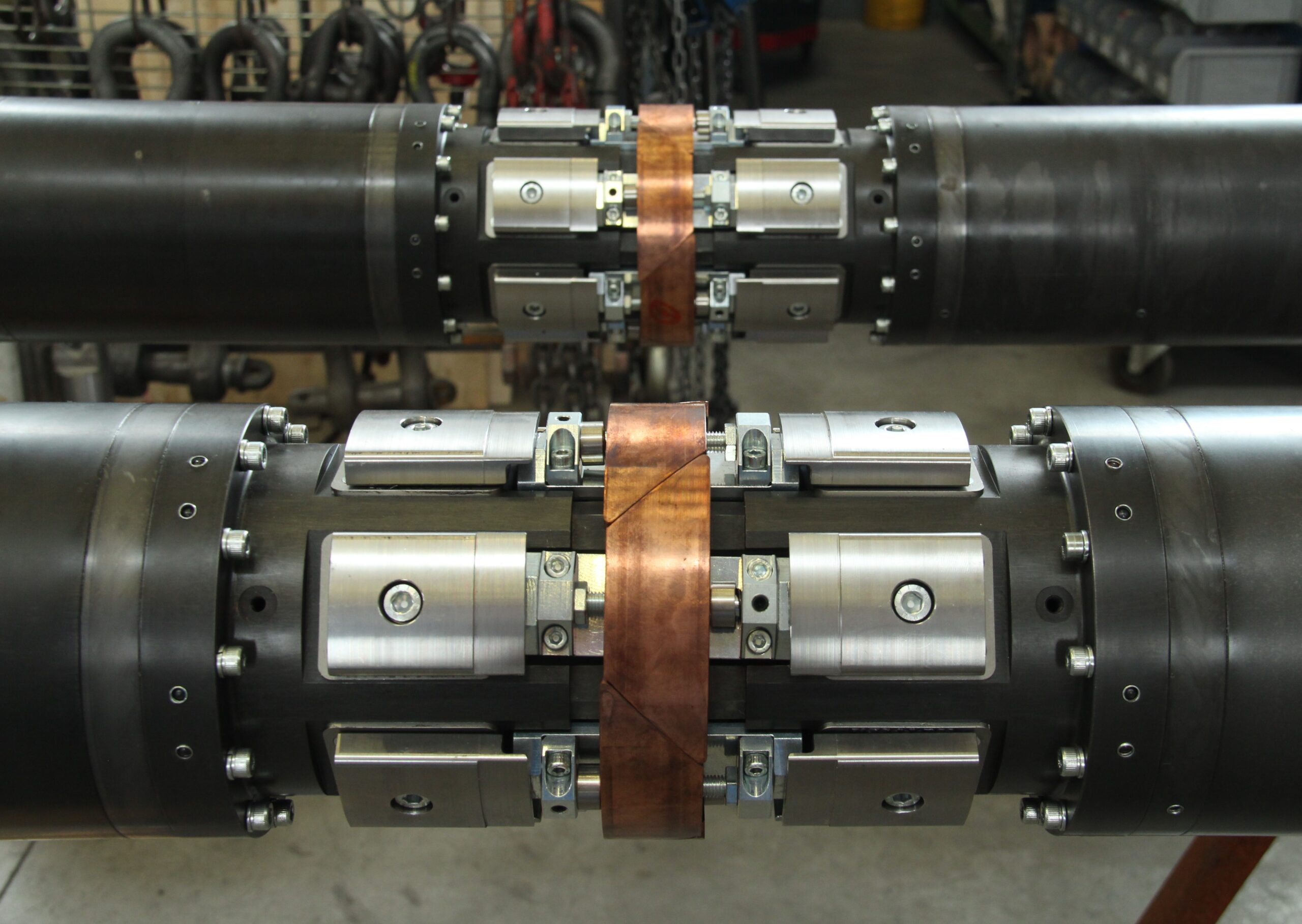

Custom Pipe Clamps solutions leverage cutting-edge materials and technologies to meet the diverse demands of industrial pipelines. From advanced alloys to polymer composites, these innovative materials offer superior strength, flexibility, and resistance to environmental factors. Additionally, integrating intelligent technologies such as sensors and monitoring systems enables real-time performance tracking and predictive maintenance, further enhancing the reliability and efficiency of pipeline operations.

Tailored Solutions for Complex Configurations:

Industrial pipelines often feature complex configurations, including bends, junctions, and varying diameters. Customized clamping solutions are adept at addressing these challenges with tailored designs that accommodate each pipeline’s specific layout and geometry. Whether designing multi-part clamps for intricate connections or developing custom brackets for unconventional installations, these bespoke solutions ensure a perfect fit and optimal performance, even in the most demanding environments.

Environmental Sustainability and Efficiency:

Customized clamping solutions contribute to environmental sustainability by minimizing material wastage and energy consumption. Through precision engineering and optimized designs, these bespoke clamps reduce the need for excess materials and facilitate more efficient operation of industrial pipelines. Minimizing leaks, spills, and emissions helps mitigate environmental impact while promoting resource conservation and responsible stewardship of natural resources.

Collaborative Design and Engineering Approach:

Developing customized clamping solutions involves a collaborative approach between engineers, designers, and stakeholders. Manufacturers can tailor solutions that align with project objectives and specifications by partnering with clients to understand their specific needs and challenges. This collaborative design process ensures the final clamping solution meets technical requirements and integrates seamlessly with existing infrastructure and operational workflows, fostering a culture of innovation and continuous improvement in industrial pipeline systems.

In industrial pipelines, customized clamping solutions represent a paradigm shift towards optimization, efficiency, and safety. By catering to the unique requirements of each application, these bespoke solutions revolutionize how pipelines are constructed, maintained, and operated. From enhancing performance and durability to ensuring compliance and cost-effectiveness, the benefits of customized clamping solutions are indisputable. In an increasingly competitive and demanding industry, embracing customization is not just a choice but necessity to stay ahead.