Packaging plays a pivotal role in the success of any product. It’s not just about protecting the contents; it’s also about catching the eye of potential consumers and conveying essential information. Among the various packaging innovations, pressure-sensitive labelers have emerged as a game-changer. These labelers have revolutionized the packaging industry by offering unparalleled versatility, convenience, and efficiency.

Let’s delve deeper into why pressure-sensitive labels have become the go-to choice for many industries and how they have transformed packaging processes.

Why Pressure-sensitive Labels?

As the name suggests, pressure-sensitive labels adhere to surfaces under pressure without needing heat, solvent, or water. This unique feature makes them incredibly versatile and suitable for various packaging applications. Whether it’s bottles, cans, jars, or boxes, pressure-sensitive labels can be applied effortlessly, ensuring a professional and attractive finish.

Benefits of Pressure-sensitive Labels:

Pressure-sensitive labels have become a staple in the packaging industry due to their numerous benefits, making them a preferred choice for brands across various sectors. Let’s delve into some of the critical advantages of pressure-sensitive labels:

1. Excellent Printability:

Pressure-sensitive labels provide a canvas for vibrant and high-quality printing. Whether it’s intricate designs, bold colors, or fine details, these labels can accommodate various printing techniques, including digital, flexographic, and offset printing. This ensures that brands can showcase their products with captivating visuals that leave a lasting impression on consumers.

2. Great Optics:

The optical properties of pressure-sensitive labels are unmatched. They can be manufactured with various finishes such as gloss, matte, or metallic, enhancing the visual appeal of packaged products. Additionally, specialty coatings like UV varnish or embossing can further elevate the aesthetics, making products stand out on crowded store shelves.

3. Known for Their Versatility:

One of the most significant advantages of pressure-sensitive labels is their versatility. They can adhere to various surfaces, including glass, plastic, metal, and even corrugated materials. This versatility makes them ideal for diverse packaging applications across industries, from food and beverage to pharmaceuticals and cosmetics.

4. Allow Accurate Positioning:

Precision is vital in packaging, especially when it comes to labeling. Pressure-sensitive labelers offer precise and consistent placement of labels, ensuring that branding elements and essential information are correctly positioned on every package. This level of accuracy enhances the overall professionalism and credibility of the product.

5. Convenient to Use:

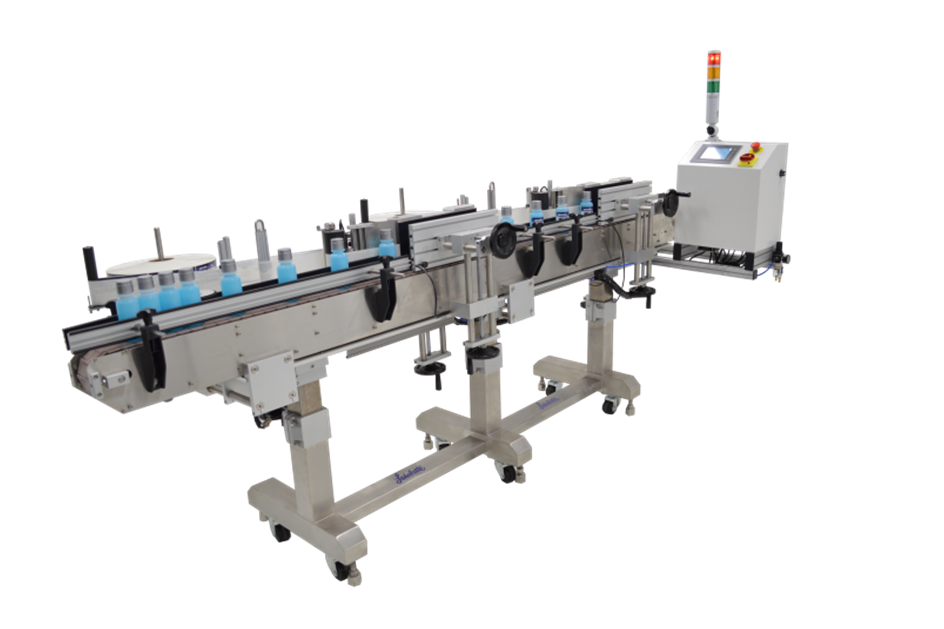

Unlike traditional labeling methods requiring specialized equipment and extensive setup, pressure-sensitive labels can be easily applied using simple machinery. Liquid filling machinery and automatic capping machines, commonly used in packaging lines, can seamlessly integrate with pressure-sensitive labelers, streamlining the entire packaging process. This convenience translates into time and cost savings for manufacturers.

How to Choose the Right Labeling Machine?

Choosing the right labeling machine is crucial to maximize the benefits of pressure-sensitive labels. Here are some steps to help you make an informed decision:

1. Assess Your Labeling Needs:

Consider factors such as production volume, label size, and application requirements. This will help you determine the labeling machine that best suits your needs.

2. Understand Labeling Technologies:

Familiarize yourself with different labeling technologies, including pressure-sensitive, hot melt, and sleeve labeling. Evaluate the pros and cons of your specific packaging requirements.

3. Research Available Options:

Explore the market for labeling machines from reputable manufacturers. Compare features, specifications, and customer reviews to narrow down your choices.

4. Consider Automation Levels:

Determine the level of automation that aligns with your production goals. From semi-automatic to fully automatic labelers, choose a machine that optimizes efficiency without compromising quality.

5. Assess Space and Installation Requirements:

Evaluate the available space in your facility and ensure that the chosen labeling machine can be easily integrated into your existing packaging line. Consider factors such as footprint, accessibility, and power requirements.

6. Factor in Maintenance and Support:

Choose a labeling machine that is easy to maintain and comes with reliable technical support. Look for features such as tool-free changeovers and remote diagnostics to minimize downtime and maximize productivity.

Bottom Line:

Pressure-sensitive labelers have transformed the packaging industry by offering unparalleled versatility, convenience, and efficiency. By leveraging the benefits of pressure-sensitive labels and choosing the suitable labeling machine, manufacturers can enhance their packaging processes, boost brand visibility, and ultimately drive sales. With advancements in technology and automation, the future of packaging looks brighter than ever before.